Knowledge And Technology

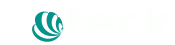

Q: How to choose a saw based on teeth per inch?

A: TPI is an acronym for Teeth Per Inch and is measured from gullet to gullet, not tooth tip to tooth tip.

In general, a saw with more teeth per inch cuts slower but leaves a cleaner finish; a saw with less teeth per inch cuts faster but leaves a rougher finish. Besides, the more teeth per inch a saw has, the harder materials the saw can cut through.

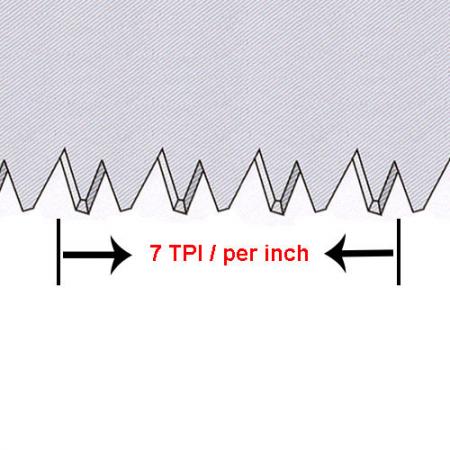

Q: Why choose a saw with triple ground teeth instead of a saw with double ground teeth?

A: Sawteeth are ground in three different angles so they are called triple ground teeth. A saw with triple ground teeth can provide smoother and more efficient cuts than a traditional saw with double ground teeth because it has sharper teeth and smoother gullets.

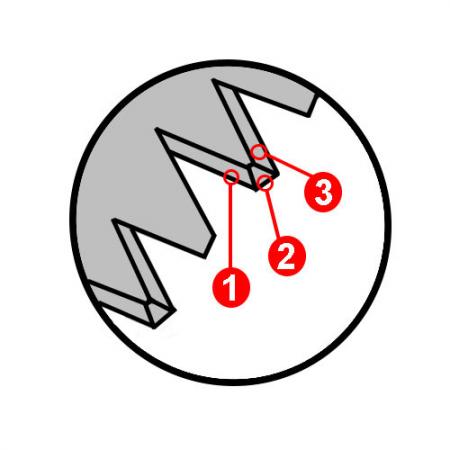

Q: What is impulse-hardening teeth?

A: Impulse hardening is the modern method of creating a saw blade with a long working life. The teeth are hardened by means of wave impulses with a very high peak power and a special high frequency. It means sawteeth will stay sharper for longer.

Q: How to buy a saw based on the thickness of the blade?

A: As a general rule, a thicker blade is firmer so higher precision and better cutting performance can be expected; a thinner blade features its flexibility so it's better to choose a thin blade if you want flush cuts or thinner cuts.

- Related Products

6inch (150mm) Deep Coping Saw with 4 Spare Blades

YU-4330

This coping saw features its four different teeth configurations for cutting different materials, 16TPI cutting wood, 20TPI cutting hardwood, 28TPI cutting plastic and 24TPI cutting metal. This coping saw blade length is 6.5 inch (165mm) and its throat depth is 6 inch (150mm). This coping saw with a strong steel frame is designed for straight and curved line cutting. The saw blade can be easily replaced by pressing down on handle held by users. The bi-material handle is cushioned for high comfort.